High Density Polyethylene Pipe

HDPE material exhibits a lot of advantages over traditional meterials for pressure pipe applications. It is eassy to process. The pipes are easy to install, light, flexible, corrosion free and can be easily welded by butt fusion or electrofusion couplers to ensure a totally leak free network. This is a flavour of the numerous advantages of polyethylene, which explains its sucessful track record usage since the beginning of the 1950's. From that time, the properties of Polyethylene has continuously been improved to answer the needs of a more and more demanding market.

Applications

- Drinkable Water Supply

- Irrigation

- Sewerage & Drainage

- Gas Transmission

- Industrial Effluents

- Conduits for Fibre Optic Cable

- Sprinkler Systems

- Chemical Industries

- Bore wells

Agriculture

- For spraying pesticides in gardens, long distant delivery of water for irrigation.

- Suction and delivery of water with pump sets.

- Drip irrigation.

- Sprinkler irrigation systems.

- Lifting water from bore wells using air compressor/jet pumps instead of gi pipes.

- Lift irrigation scheme

- For submersible pumps / column pipes instead of gi pipes.

- Potable water supply

- Water supply in rural and urban areas-even in sub-zero temperatures at high altitudes.

Industrial

- Conveying corrosive effluents of chemical and other process industries like petrochemicals, paper, dye-stuffs, paints, rayon and fertilisers

- Protective outer cover for telephone cable conduits and telephone duct

- Conveying treated radio-active waste. Handling edible oils, fruit juices pulps, milk and other food material.

- Conveying acids, alkalis and other corrosive chemicals.

- Chilled water circulation.

- Conveying of sewage, drainage(outside and underground)

- Air conditioning and ducting

- Handling of salt water.

Features

- Eco friendly

- Tough and Strong

- 100% hygienic

- Smooth internal surface

- Durable and light weight

- Flexible

- Weather resistant

- Wear and abrasion resistant

- inert to chemicals

- Quick and easy installation

- length as required

- 50 years lifespan

- Economical

- Maintenance free

- Energy saving

High Density Polyethylene Pipe

Light weight & durable. High flow capacity. Abrasion resistance. Weather / Chemical resistance

Product Range

- Available in size ranging from 16mm - 110mmin 2.5, 4.0, 6.0, 8.0, 10.0, 12.5 and 16kg/cm2 pressure rating.

- Size ranging from 16mm to 110mm for suction, submersible and jet pump applications.

- Pressure class depends upon the depth of the bore.

Recommendations

| Depth of the Bore in mtrs |

Pressure Class |

| Up to 55 mtrs |

4.0 kg/cm2 |

| Up to 90 mtrs |

6.0kg/cm2 |

| Up to 140 mtrs |

10.0kg/cm2 |

| Up to 170 mtrs |

12.5kg/cm2 |

Length / Packing

| Size Range |

Length |

| 16mm to 50mm |

500 mtrs standard |

| 63mm to 90mm |

300 mtrs standard |

| 110mm |

up to 200 mtrs / in straight length of 6 mtrs |

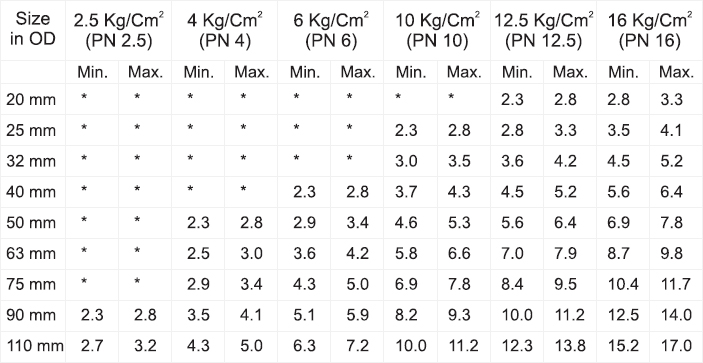

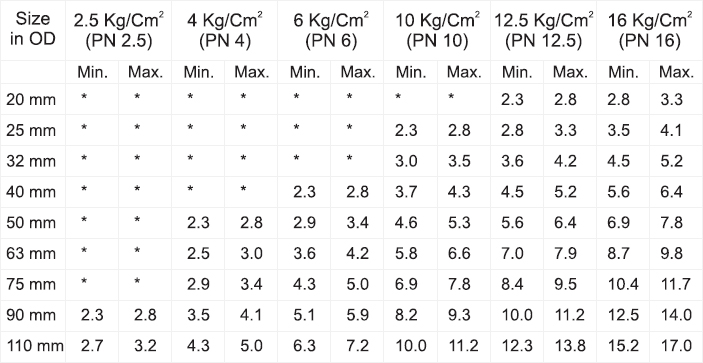

Dimensional detail for HDPE pipe made as per IS: 4984

(wall thickness of pipes for material grade PE 63)

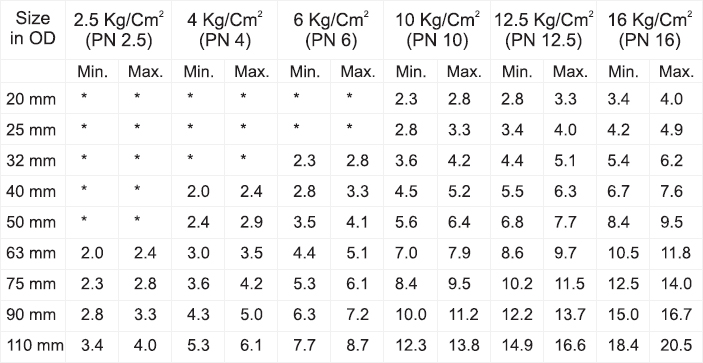

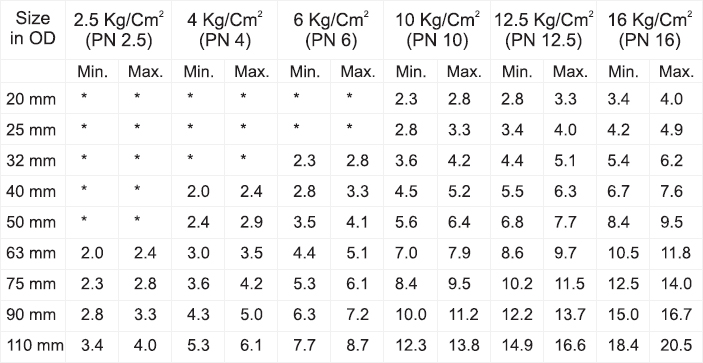

Dimensional detail for HDPE pipe made as per IS: 4984

(wall thickness of pipes for material grade PE 80)